Scheduling in field service always starts with good intentions. Somewhere, usually the night before, a clean, logical schedule exists. It has neat time slots, sensible travel paths, and a comforting sense of order. Then the day begins, and scheduling immediately reminds everyone that it has a personality of its own.

On paper, scheduling looks like a math problem. In real life, it behaves more like a relationship. It is emotional. It is unpredictable. And it has a habit of going off-plan the moment you stop paying attention.

The first misunderstanding usually happens around availability. A technician appears free on the schedule, so the job gets assigned. What the schedule does not show is whether that technician has the right skills, the right parts, or any interest in driving across the city during rush hour. Availability does not equal suitability, but scheduling often pretends it does. When that happens, first-time fix rates suffer and the rest of the day quietly slides out of alignment.

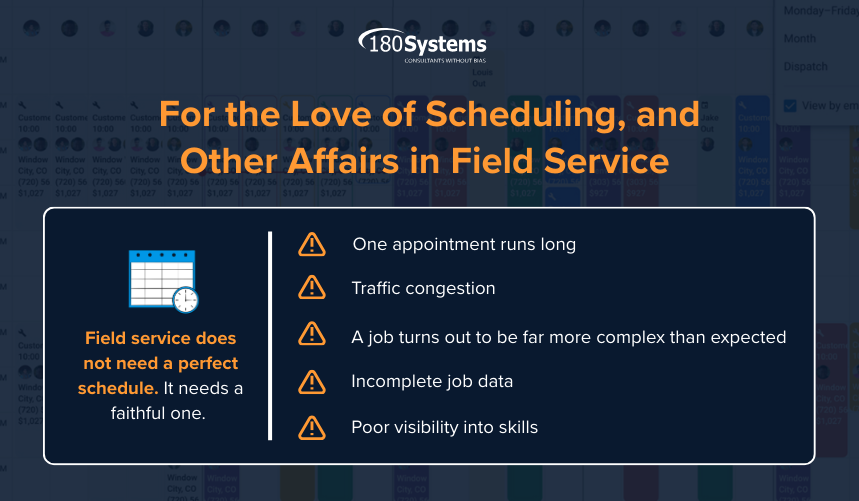

Then there is the optimistic stacking of jobs. Everything looks fine until one appointment runs long, traffic builds, or a job turns out to be far more complex than expected. Suddenly the schedule resembles a tightrope act with no safety net. Dispatch is fielding calls. Technicians are apologising. Customers are watching arrival windows drift by. No one is surprised, but everyone is inconvenienced.

Emergency work adds its own drama. It always arrives uninvited and always expects immediate attention. The schedule, carefully built over hours, collapses in seconds. The rest of the day becomes a series of compromises. Someone gets bumped. Someone gets rushed. Someone gets frustrated. Scheduling did not fail exactly; it just did not stand a chance.

What makes scheduling especially tricky is that it rarely fails loudly. It fails politely. A few minutes late here. A return visit there. A bit of overtime that feels manageable. Over time, those small issues turn into higher fuel costs, exhausted technicians, and customers who stop believing in arrival windows altogether. By the time leadership notices, the damage is already baked into the numbers.

It is tempting to treat scheduling as a dispatch problem. If only dispatch worked harder, planned better, or had one more tool. In reality, scheduling issues usually point to deeper problems. Incomplete job data. Poor visibility into skills. Inventory that does not talk to scheduling. Priorities that change faster than the system can keep up. Dispatch ends up managing the fallout rather than controlling the plan.

Better scheduling does not come from trying to make every day perfect. It comes from planning based on how work typically unfolds. Skills-based scheduling matters more than proximity. Complete and accurate job data matters more than speed. Small, deliberate allowances for variability help schedules stay intact and reduce downstream disruption. When systems reflect real operating conditions, scheduling becomes more reliable and easier to manage.

Clear communication also helps. Customers appreciate transparency more than false precision. Technicians appreciate knowing what they are walking into. Dispatch appreciates not having to guess. Scheduling improves when everyone is working from the same version of reality.

Scheduling will never be flawless. There will always be traffic, late calls, and unexpected complications. But when treated as part of a broader system rather than a daily emergency, it becomes calmer, more predictable, and far less exhausting for everyone involved.

Field service does not need a perfect schedule. It needs a faithful one. And that, more than anything, is what keeps the day from turning into another affair nobody planned for.

ytwxt2

A really good blog and me back again.

Boost your income effortlessly—join our affiliate network now!

Join our affiliate family and watch your profits soar—sign up today!

Be rewarded for every click—join our affiliate program today!

Promote our products and earn real money—apply today!

reb3ek

Partner with us and enjoy recurring commission payouts!

Get rewarded for every recommendation—join our affiliate network!

Join our affiliate program and start earning commissions today—sign up now!

Share our offers and watch your wallet grow—become an affiliate!

Start sharing our link and start earning today!